Water Supply

Garden irrigation and cleaning of outdoor areas – clever, inexpensive and environmentally friendly using rainwater

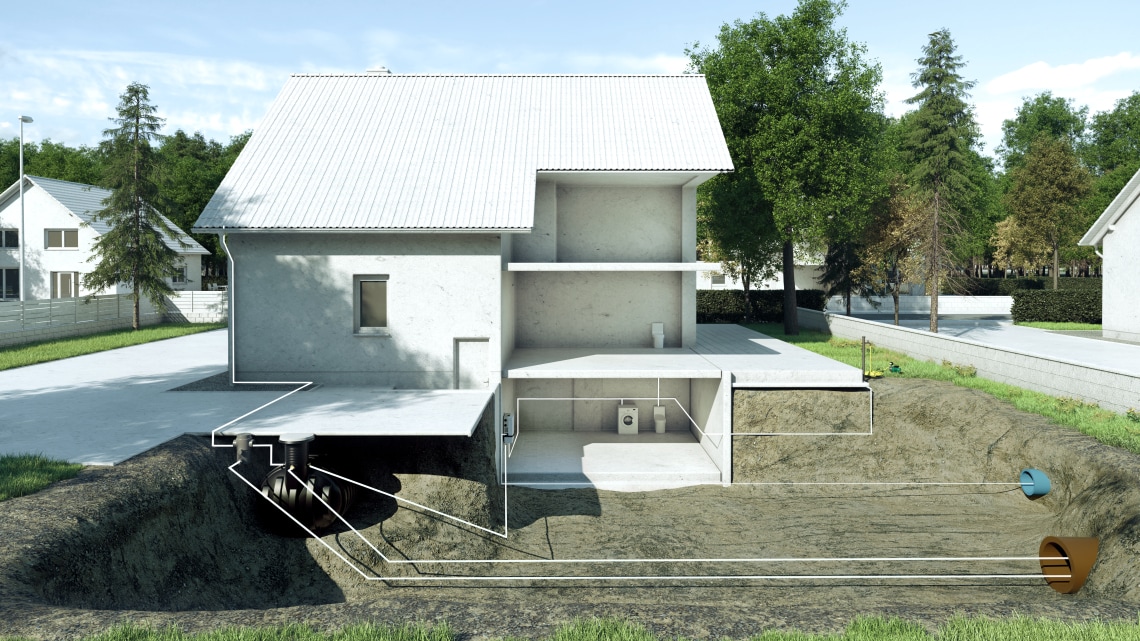

Rainwater utilisation systems from Wilo pump water directly to the extraction points in the property. Rational use of rainwater is clever, inexpensive and environmentally friendly. With specially designed systems from Wilo, about 50 % of the daily water requirement can be met using rainwater. This way, you can protect the environment and your household budget. Use the valuable liquid that nature provides: With rainwater, you can irrigate your garden and clean your outdoor areas, like patios or garden paths – an inexpensive and environmentally friendly alternative to using drinking water. A rainwater reservoir in combination with a needs-based rainwater utilisation system ensures uniform and low-noise irrigation. Sprinkling, watering, irrigating and cleaning – where drinking water is too expensive, rainwater utilisation is recommended, using a complete system from Wilo.

Rainwater utilisation systems from Wilo pump water directly to the extraction points in the property. Rational use of rainwater is clever, inexpensive and environmentally friendly. With specially designed systems from Wilo, about 50 % of the daily water requirement can be met using rainwater. This way, you can protect the environment and your household budget. Use the valuable liquid that nature provides: With rainwater, you can irrigate your garden and clean your outdoor areas, like patios or garden paths – an inexpensive and environmentally friendly alternative to using drinking water. A rainwater reservoir in combination with a needs-based rainwater utilisation system ensures uniform and low-noise irrigation. Sprinkling, watering, irrigating and cleaning – where drinking water is too expensive, rainwater utilisation is recommended, using a complete system from Wilo.

Continuous power at the highest level

Reliable supply of water in static high-lying taps. Fluctuating water consumption in different types of buildings, such as schools, hospitals or hotels, requires flexible systems which meet individual demands. When gravitational systems such as water towers cannot be used for the water supply due to spatial conditions, a system is required to boost the pressure. These systems provide adequate water pressure in high-rise buildings, in high-altitude inhabited areas and in plant systems, either in supply or circulation systems. Using Wilo pressure-boosting systems, you can ensure that water will be supplied reliably.

Customised Wilo solutions for optimal water pressure

Especially in the case of residential areas that have grown up over time or attic conversions, the pressure cannot be maintained above and immediately below water reservoirs. Therefore, a pressure-boosting system might also be required in residential buildings. Buildings such as apartment blocks, schools, hospitals and hotels place considerable demands on the water supply on all floors. Wilo provides flexible systems for pressure boosting for every installation location to enable a convenient and reliable supply of water. What’s more, a self-priming pump from Wilo is the ideal solution for outdoor cleaning purposes or for plant irrigation. It can be set up next to ponds, lakes, streams or rainwater barrels. This saves on costly precious tap water.

Especially in the case of residential areas that have grown up over time or attic conversions, the pressure cannot be maintained above and immediately below water reservoirs. Therefore, a pressure-boosting system might also be required in residential buildings. Buildings such as apartment blocks, schools, hospitals and hotels place considerable demands on the water supply on all floors. Wilo provides flexible systems for pressure boosting for every installation location to enable a convenient and reliable supply of water. What’s more, a self-priming pump from Wilo is the ideal solution for outdoor cleaning purposes or for plant irrigation. It can be set up next to ponds, lakes, streams or rainwater barrels. This saves on costly precious tap water.

Solution for wells and surface waters

Wherever large quantities of water are needed, the extraction of surface water is also a frequent option. Water is pumped and transferred, for water purification for example, by using shallow wells in lakes or rivers.

The establishment and management of wells are major cost factors in water supply. Of great importance is extensive knowledge in geohydrology, water quality, water resource development options and materials, as well as flow conditions at the well. Having your own well or borehole makes you independent of expensive drinking water and rainwater that is only limitedly available. Wilo submersible pumps will help you pump ground water and irrigate larger areas reliably and easily.

Reliable solutions for all volume flows

Municipal suppliers as well as industry require large quantities of water on a daily basis. Efficient methods and the development of new sources such as desalinated seawater or aquifers (ground water pipes) are possible options for securing future supplies. Ecologically and economically high standards are already being applied to the production of water from lakes, dams, rivers, and seas. A well offers great potential for savings if the pump is operating at its optimum duty point. Wilo submersible pumps can be precisely adjusted to operating conditions. The installation depth and well yield determine which pump to use. The selection criteria are optimal efficiency for minimising energy costs and the use of suitable materials for long-term and maintenance-free pumping operation. In addition, precise trimming of the impeller diameter enables the desired delivery rates to be established precisely. This guarantees you an economical solution. We can handle even fluctuating water levels, for example behind dams, with optimum levels of efficiency and a high degree of operational reliability. For the extraction of water containing corrosive and abrasive elements we use resistant materials such as duplex and coatings like Ceram or Ceram CT. They withstand attacks from aggressive substances and allow long-term pumping operation.

Municipal suppliers as well as industry require large quantities of water on a daily basis. Efficient methods and the development of new sources such as desalinated seawater or aquifers (ground water pipes) are possible options for securing future supplies. Ecologically and economically high standards are already being applied to the production of water from lakes, dams, rivers, and seas. A well offers great potential for savings if the pump is operating at its optimum duty point. Wilo submersible pumps can be precisely adjusted to operating conditions. The installation depth and well yield determine which pump to use. The selection criteria are optimal efficiency for minimising energy costs and the use of suitable materials for long-term and maintenance-free pumping operation. In addition, precise trimming of the impeller diameter enables the desired delivery rates to be established precisely. This guarantees you an economical solution. We can handle even fluctuating water levels, for example behind dams, with optimum levels of efficiency and a high degree of operational reliability. For the extraction of water containing corrosive and abrasive elements we use resistant materials such as duplex and coatings like Ceram or Ceram CT. They withstand attacks from aggressive substances and allow long-term pumping operation.

Fire protection and drinking water

Fire-extinguishing and fire protection systems only get used in the event of a fire. They are filled with water and if not flushed, there is the danger that the water could become hygienically unsafe. If such systems are connected to a drinking water installation, they pose a danger to the drinking water. Stagnant water typically forms in fire-extinguishing systems. Stagnant water may lead to pathogenic germs forming. Under DIN 1988 and DIN EN 1717, process water systems such as fire-extinguishing systems are required to be isolated from public drinking water system, e.g. by means of free outflow protection devices (type: AA, AB). The potential hazard of bacteriological re-contamination of domestic and public drinking water systems has to be eliminated by law. In the drinking water separator station from WILO IndustrieSysteme, the certified free outflow type AB is integrated.

Ready for use in every instance

Different building situations, combined with different regional regulations, require specific solutions. Fire-extinguishing systems can be individually assembled with high-quality Wilo components. Profit from our expertise and our highly efficient pump technology. For example, with fully automatic water-supply units in a robust system made up of energy-efficient high-pressure centrifugal pumps and standard motors.

Different building situations, combined with different regional regulations, require specific solutions. Fire-extinguishing systems can be individually assembled with high-quality Wilo components. Profit from our expertise and our highly efficient pump technology. For example, with fully automatic water-supply units in a robust system made up of energy-efficient high-pressure centrifugal pumps and standard motors.

Wilo high-efficiency pumps for firefighting offer solutions specific to the industrial sector and ensure compliance with regional regulations. Our solutions meet the requirements of DIN 14462 for the maximum protection of people, goods and buildings. Just as important is the absolute operational reliability in the event of a fire.

Wilo offers high-quality complete systems for reliable and safe fire water usage. The fire-extinguishing systems from Wilo are particularly suitable

- For wall and exterior hydrants

- For sprinkler systems in addition to wall and exterior hydrants

- For high-rise buildings and properties

Beautiful mountains and long valleys are any walker’s dream. For a water utility company, however, this scenario sets a highly complex set of challenges. Efficient pumps that can constantly provide suitable pressure and good planning are necessary to reliably supply regions that have significant differences in elevation and numerous consumption points that are spread out.

However, even in areas that are less geographically striking, water still has to be transported over long distances and distributed. Especially in large cities with numerous tall and large buildings, distribution at the correct pressure is a challenge that should not be underestimated as it necessitates a huge distribution network of pipes.

Efficient pressure management from the waterworks to the

Reliable and trouble-free supply of water is necessary to guarantee the living standards and health of the population. Old pipework often constitutes a problem as it becomes porous when constantly subjected to water pressure. This, in turn, causes cracks through which water is lost. To prevent this sort of water loss, the water pipe system is constantly inspected by electronic devices. Another means of minimizing the losses due to excessive pressure in the pipes is the selection of the right pump with an efficient pressure management. Reliable, intelligent Wilo pumps ensure that the desired pressure is always provided to the end consumer and any losses and the associated costs are kept to an absolute minimum.

Reliable and trouble-free supply of water is necessary to guarantee the living standards and health of the population. Old pipework often constitutes a problem as it becomes porous when constantly subjected to water pressure. This, in turn, causes cracks through which water is lost. To prevent this sort of water loss, the water pipe system is constantly inspected by electronic devices. Another means of minimizing the losses due to excessive pressure in the pipes is the selection of the right pump with an efficient pressure management. Reliable, intelligent Wilo pumps ensure that the desired pressure is always provided to the end consumer and any losses and the associated costs are kept to an absolute minimum.

In the agricultural sector, a sustainable approach to the use of water is a basic requirement for the production of natural food under constantly changing climatic conditions. The changing climate noticeably affects production in many regions of the world. Irrigation is necessary under such conditions to secure the crop yields. Other conditions such as too little precipitation or severely fluctuating precipitation also necessitate irrigation to balance out the natural water supply. Irrigation is the key to turning vast areas into usable, fertile land, which would otherwise lie dry and barren. For this reason, artificial irrigation is used worldwide for the husbandry of around 150 million hectares of land.

Modern irrigation systems for agriculture

Modern field irrigation provides differing options for supplying the root systems with ample amounts of water. The water requirement depends significantly on the type of crop sown, the soil conditions and the climate.

Applications in professional irrigation/agriculture

Differing pump systems and irrigation systems are needed to ensure all plants get enough water. Especially in dry regions, it is important to extract and deliver irrigation water as effectively as possible. Wilo has the necessary expertise and the right technologies. Wilo borehole pumps and turbines ensure, for example, that water can be drawn from the ground or from water pipes to safeguard the required supply.

Not all farmers have the same conditions for pumping water. That is why Wilo has developed pumps that can be positioned freely. For example, they can be located quite feasibly on a float to simply pump water from a river or lake. Wilo’s glanded pumps are tried and trusted in practice. They allow you draw off the amount of water you require regardless of the respective water level and transport it precisely to where it is needed.

On large flat surfaces there is often not enough water pressure to secure supply, especially where water levels fluctuate severely. This is where high-efficiency pressure-boosting systems from Wilo come in. They make sure that all of the plants on your fields aresufficiently watered at the right water pressure. That guarantees supply at a constant pressure, even with fluctuating water levels; all done in the most energy-efficient manner possible.

PRESSURE BOOSTING PRODUCTS

Series Description

PDF:Wilo-Comfort CO-/COR-MVI.../CC

PDF:Wilo-Comfort CO-/COR-MVI.../CC

Technical data

- Mains connection 3~230 V/400 V ± 10%, 50 Hz

- Max. fluid temperature 50 °C (70 °C optional)

- Operating pressure 16 bar (25 bar optional)

- Inlet pressure 10 bar

- Nominal connection diameters on discharge side R 1½ - DN 200

- Nominal connection diameter on the intake side R 1½" - DN 200

- Rated speed 2850 rpm

- Protection class IP 54 (CC control device)

- Fuse protection on mains side AC 3 according to motor power and EVU regulations

- Approved fluids (other fluids on request):Note on fluids: Approved fluids are generally water mixtures which do not chemically or mechanically attack the materials used and do not contain either abrasive or fibrous matter

- Drinking water and domestic hot water

- Cooling water

- Fire water

Special features/product advantages

- Easy-to-operate system in accordance with DIN 1988

- 2-6 vertical stainless steel high-pressure centrifugal pumps, switched in parallel, of the MVI series

- Easy-to-use "CC" control device, with memory-programmable microcomputer control and completely graphics-capable touch display, menu-prompted input of operating parameters, available with frequency converter for infinitely variable control of the base-load pump with COR systems

Design type

Pressure boosting system with 2 to 6 parallel-switched, non self-priming stainless steel high-pressure multistage centrifugal pumps

Application

- Fully automatic water supply and pressure boosting in residential, commercial and public buildings, hotels, hospitals, department stores and for industrial systems.

- Pumping of drinking water and process water, cooling water, fire water (apart from fire-extinguishing systems in accordance with DIN 14462 and with the approval of the local fire safety authorities) or other types of industrial water that do not attack the materials either chemically or mechanically and do not contain abrasive or long-fibre constituents.

Equipment/function

- 2-6 pumps of the MVI series per system

- Automatic pump control via CC Controller

- Components that come in contact with fluid are corrosion-resistant

- Base frame galvanised, with height-adjustable vibration absorbers for insulation against structure-borne noise

- Check valve at each pump, on the suction and pressure sides

- Non-return valve, pressure side

- Diaphragm pressure vessel 8 l, PN16, pressure side

- Pressure sensor, on the discharge side

- Optional pressure gauge, suction side

- Pressure gauge, discharge side

- Optional low-water cut-out switchgear

Scope of delivery

- Factory-mounted, connection-ready pressure boosting system checked for functionality and impermeability

- Packaging

- Installation and operating instructions

Type key

| Example: | Wilo-COR-4 MVI 804/CC |

| CO | Compact pressure boosting system |

| R | Control of the respective base-load pump by frequency converters |

| 4 | Number of pumps |

| MVI | Pump series |

| 8 | Rated volume flow of the single pump [m3/h] |

| 04 | Number of single-pump stages |

| CC | Control unit; CC = Comfort-Controller |

Materials

MVI 1.. to 16..-6

- Impellers and stage chambers made of 1.4301/1.4404 stainless steel (MVI 16..-6 only in 1.4301)

- Pump housing made of 1.4301/1.4404 stainless steel

- Shaft 1.4301/1.4404 stainless steel

- Gasket EPDM (EP 851) / FKM (Viton)

- Housing cover made of 1.4301/1.4404 stainless steel

- Housing bottom 1.4301/1.4404 stainless steel

- Mechanical seal B-carbon/tungsten carbide, SiC/carbon

- Pressure shroud 1.4301/1.4404 stainless steel

- Bearing, tungsten carbide

- Pump base EN-GJL-250

- Pipework made of 1.4571 stainless steel

MVI 16.. to 95..

- Impellers 1.4301/1.4404 stainless steel

- Stage chambers 1.4301/1.4404 stainless steel

- Pump housing EN-GJL-250/1.4404

- Shaft 1.4057/1.4404 stainless steel

- Gasket EPDM (EP 851) / FKM (Viton)

- Housing cover made of 1.4301/1.4404 stainless steel

- Housing bottom 1.4301/1.4404 stainless steel

- Mechanical seal B-carbon/tungsten carbide, SiC/carbon

- Pressure shroud 1.4301/1.4404 stainless steel

- Bearing, tungsten carbide

- Pipework made of 1.4571 stainless steel

Description/construction

- Base frame: galvanised and provided with height-adjustable vibration absorbers for comprehensive insulation against structure-borne noise; other versions on request

- Pipework: complete pipework made of stainless steel, suitable for the connection of all piping materials used in building services; the pipework is dimensioned according to the overall hydraulic performance of the pressure boosting system

- Pumps: 2 to 6 pumps of the MVI 2 to MVI 95 series switched in parallel are used; all pump components in contact with fluid are made of stainless or, starting with MVI 16.., of grey cast iron (cataphoretic-coated) or stainless steel on request

- Valves: each pump is fitted on the suction and pressure side with a check valve with DVGW approval mark or annular shut-off valves and a pressure-side DVGW-approved non-return valve

- Diaphragm pressure vessel: 8 l/PN 16 located on the discharge side with a butyl rubber diaphragm, completely safe in accordance with food safety laws, for testing and inspection purposes, with ball valve, with drain and throughflow fitting according to DIN 4807

- Pressure sensor: 4 to 20 mA, located on the discharge side for activating the central Comfort Controller

- Pressure display: suction- and discharge-side pressure gauge (ø 63 mm); additional digital display of discharge pressure in the alphanumeric touchscreen of the Comfort Controller.

- Switchgear/controller: the system is equipped with a CC Comfort Controller as standard; COR additionally with a frequency converter

Downloads

Products

| Product description | Control | Mains connection | Maximum operating pressure PN | Number of standby pumps | System output without standby pump Q | Gross weight, approx. m | Article number |

|---|---|---|---|---|---|---|---|

| Comfort COR-2 MVI 7001/1/CC | With frequency converter | 3~400 V, 50 Hz | 16 bar | 1 | 100.0 m³/h | 586.0 kg | 2523245 |

| Comfort COR-2 MVI 7001/CC | With frequency converter | 3~400 V, 50 Hz | 16 bar | 1 | 100.0 m³/h | 687.0 kg | 2523246 |

| Comfort COR-2 MVI 7002/2/CC | With frequency converter | 3~400 V, 50 Hz | 16 bar | 1 | 100.0 m³/h | 738.0 kg | 2523247 |

| Comfort COR-2 MVI 7002/CC | With frequency converter | 3~400 V, 50 Hz | 16 bar | 1 | 100.0 m³/h | 810.0 kg | 2523248 |

| Comfort COR-2 MVI 7003/2/CC | With frequency converter | 3~400 V, 50 Hz | 16 bar | 1 | 100.0 m³/h | 838.0 kg | 2523249 |

| Comfort COR-2 MVI 7003/CC | With frequency converter | 3~400 V, 50 Hz | 16 bar | 1 | 100.0 m³/h | 960.0 kg | 2523250 |

| Comfort COR-2 MVI 7004/2/CC | With frequency converter | 3~400 V, 50 Hz | 16 bar | 1 | 100.0 m³/h | 968.0 kg | 2523251 |

| Comfort COR-2 MVI 7004/CC | With frequency converter | 3~400 V, 50 Hz | 16 bar | 1 | 100.0 m³/h | 1014.0 kg | 2523252 |

| Comfort COR-2 MVI 7005/2/CC | With frequency converter | 3~400 V, 50 Hz | 16 bar | 1 | 100.0 m³/h | 1236.0 kg | 2523253 |

| Comfort COR-2 MVI 7005/CC | With frequency converter | 3~400 V, 50 Hz | 16 bar | 1 | 100.0 m³/h | 1236.0 kg | 2523254 |

| Comfort COR-2 MVI 7006/2/CC | With frequency converter | 3~400 V, 50 Hz | 25 bar | 1 | 100.0 m³/h | 1303.0 kg | 2523255 |

| Comfort COR-2 MVI 7006/CC | With frequency converter | 3~400 V, 50 Hz | 25 bar | 1 | 100.0 m³/h | 1347.0 kg | 2523256 |

Series Description

Technical data

- Electrical connection: 3~400 V (±10 %), 50 Hz

- ≤ 4 kW 230 V/ 400 V; Δ/Y

- > 4 kW 400 V/ 690 V; Δ/Y

- Fluid temperature range:

- Helix V 2 – 16 (EPDM): -30 to 120 °C (130 °C on request)

- Helix V 2 – 16 for aggressive media (FKM): -15 to 90 °C

- Helix V22 – 52 (EPDM): -20 to 120 °C (130 °C on request)

- Helix V22 – 52 for aggressive media (FKM): -15 to 90 °C

- Max. operating pressure: 16/25/30 bar

- Protection class: IP 55

- Max. ambient temperature: +40°C (extended temperature ranges on request)

- Available versions:

- Helix V 2 – 16: PN 16 with oval flanges, PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005 (Victaulic coupling on request)

- Helix V 22 – 52: PN 16/PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005

Materials

Helix V 2, 4, 6, 10, 16:

Standard version

- Impellers, stage housings and guide vanes made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4301 (AISI 304)

- Baseplate and lantern in EN-GJL-250 (cataphoretic coated)

- Shaft made of stainless steel 1.4301 (AISI 304) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

For aggressive media

- Impellers, stage housings and guide vane apparatuses of stainless steel 1.4404 (AISI 316L)

- Pump housing made of stainless steel 1.4404 (AISI 316L)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Jacket pipe made of stainless steel 1.4404 (AISI 316L)

Helix V 22, 36, 52:

Standard version

- Stage housings, impellers, guide vane apparatuses made of stainless steel 1.4307 (AISI 304L)

- Pump housing made of stainless steel 1.4308 (AISI 304) or cataphoretic-coated grey cast iron EN-GJL 250, loose flanges made of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Shaft made of stainless steel 1.4057 (AISI 431)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of EPDM (FKM gasket on request)

- Jacket pipe made of stainless steel 1.4301 (AISI 304)

For aggressive media

- Stage housings, impellers, and guide vane apparatuses made of stainless steel 1.4404 (AISI 316L)

- Pump housing: all parts which come in contact with the media are made of cast stainless steel 1.4409 (AISI 316L); loose flanges of cataphoretic-coated grey cast iron EN-GJL 250 for Helix V 22 / EN-GJS 400 for Helix V 36-52.

- Baseplate made of stainless steel 1.4301 (AISI 304)

- Shaft made of stainless steel 1.4404 (AISI 316L) or 1.4462 (AISI 318LN) (depending on version)

- Sleeve under the mechanical seal 1.4404 (AISI 316L)

- O-ring of FKM (EPDM gasket on request)

- Pressure shroud made of stainless steel 1.4404 (AISI 316L)

Description/construction

- Pumps can be adapted to specific circumstances on request (e.g. motor protection, ATEX, extended ambient temperature range).

- The Helix series is also available with an integrated frequency converter.

Special features/product advantages

- Efficiency-optimised, laser-welded 2D/3D hydraulics, flow and degassing optimised

- Corrosion-resistant impellers, guide vanes and stage housings

- Flow and NPSH-optimised pump housing

- Maintenance-friendly design with particularly robust coupling guard

- Drinking water approval for pumps with parts that come in contact with the fluid made of stainless steel (EPDM version)

Design type

Non-self-priming, high-efficiency multistage high-pressure centrifugal pump in vertical design with in-line connections

Application

- Water supply and pressure boosting

- Industrial circulation systems

- Process water

- Closed cooling circuits

- Fire extinguishing systems

- Washing systems

- Irrigation

Equipment/function

- Corrosion-resistant impellers, guide vanes and stage housings

Scope of delivery

- Helix V high-pressure multistage centrifugal pump

- Installation and operating instructions

- Helix V 2 – 16 (version PN16 with oval flanges): counter flanges made of stainless steel with the corresponding screws, nuts and gaskets

Type key

| Example: | Helix V 2202/2-1/16/E/X/KS/../400-50 |

| Helix V | Vertical high-pressure multistage centrifugal pump in in-line design |

| 22 | Flow rate in m3/h |

| 02 | Number of impellers |

| 2 | Number of trimmed impellers (optionally) |

| 1 | Pump material |

| 1 = Pump housing 1.4301 (AISI 304) Hydraulics 1.4307 (AISI 304L) | |

| 2 = Pump housing 1.4409 (AISI 316L) Hydraulics 1.4404 (AISI 316L) | |

| 3 = Pump housing EN-GJL-250 (cataphoretic-coated) Hydraulics 1.4307 (AISI 304L) | |

| 4 = Monobloc pump housing EN-GJL-250 (cataphoretic-coated) Hydraulics 1.4307 (AISI 304L) [Only Helix VE 22.. and larger] | |

| 16 | Maximum operating pressure in bar |

| 16 = 16 bar (PN 16 flange) | |

| 25 = 25 bar (PN 25 flange) | |

| 30 = 30 bar (PN 40 flange) | |

| E | Gasket type E = EPDM V = FKM |

| X | "X-Care" special version |

| K | Cartridge type mechanical seal |

| S | The coupling guard is on a line with suction and discharge ports of the pump. |

| .. | Optional |

| 400 | Connection voltage in V |

| 50 | Frequency in Hz |

Downloads

Products

| Product description | Rated power P2 | Pump connection | Cartridge | Gross weight, approx. m | Article number |

|---|---|---|---|---|---|

| Helix V 202-1/16/E/KS | 0.37 kW | G 1 | Cartridge mechanical seal | 26.0 kg | 4161704 |

| Helix V 203-1/16/E/KS | 0.37 kW | G 1 | Cartridge mechanical seal | 27.0 kg | 4161705 |

| Helix V 204-1/16/E/KS | 0.37 kW | G 1 | Cartridge mechanical seal | 27.0 kg | 4161706 |

| Helix V 205-1/16/E/KS | 0.55 kW | G 1 | Cartridge mechanical seal | 32.0 kg | 4161707 |

| Helix V 206-1/16/E/KS | 0.55 kW | G 1 | Cartridge mechanical seal | 32.0 kg | 4161708 |

| Helix V 207-1/16/E/KS | 0.55 kW | G 1 | Cartridge mechanical seal | 33.0 kg | 4161709 |

| Helix V 208-1/16/E/KS | 0.75 kW | G 1 | Cartridge mechanical seal | 38.0 kg | 4161710 |

| Helix V 209-1/16/E/KS | 0.75 kW | G 1 | Cartridge mechanical seal | 38.0 kg | 4161711 |

| Helix V 210-1/16/E/KS | 0.75 kW | G 1 | Cartridge mechanical seal | 39.0 kg | 4161713 |

| Helix V 211-1/16/E/KS | 1.10 kW | G 1 | Cartridge mechanical seal | 41.0 kg | 4161715 |

| Helix V 212-1/16/E/KS | 1.10 kW | G 1 | Cartridge mechanical seal | 44.0 kg | 4161717 |

| Helix V 213-1/16/E/KS | 1.10 kW | G 1 | Cartridge mechanical seal | 45.0 kg | 4161719 |

Series Description

Type key

| Example: | MHI 205-1/E/3-400-50-2-IE3 |

| MHI | Multistage horizontal high-pressure centrifugal pump |

| 2 | Flow rate in m3/h |

| 05 | Number of impellers |

| 1 | Material 1 = 1.4301 (AISI 304) 2 = 1.4404 (AISI 316L) |

| E | Gasket type E = EPDM V = FKM (Viton) |

| 3 | 1 = 1~ (alternating current) 3 = 3~ (three-phase current) |

| 400 | Connection voltage in V |

| 50 | Frequency in Hz |

| 2 | Number of poles |

| IE3 | IE3 motor |

Technical data

- Mains connection 1~230 V (±10 %), 50 Hz or optionally 220 V (±10 %), 60 Hz

- Mains connection: 3~230 V (±10 %), 50 Hz (Δ) or optionally 265 V (±10 %), 60 Hz (Δ), 400 V (±10 %), 50 Hz (Y) or optionally 460 V (±10 %), 60 Hz (Y); same motor also: 3~220 V (±10 %), 60 Hz (Δ), 380 V (±10 %), 60 Hz (Y);

- Fluid temperature of -15 to +110 °C

- Max. operating pressure 10 bar

- Max. inlet pressure of 6 bar

- Protection class 1~: IPX4; 3~: IP54

- Nominal diameters of pipe connections: Rp 1, Rp 1 ¼ or Rp 1 ½, depending on type

Materials

- Impellers, stage chambers and pump housing made of 1.4301/1.4404 stainless steel

- Shaft 1.43.01 or 1.4404 stainless steel

- Seal EPDM (EP 851) / FKM (Viton)

- EPDM version of mechanical seal: B carbon/silicon carbide, FKM version: Silicon carbide/B-carbon

- Bearing tungsten carbide/aluminium oxide

- Pump support foot aluminium

Special features/product advantages

- IE3 IEC three-phase AC motor (≥ 0.75 kW)

- All parts that come in contact with the fluid are made of stainless steel 1.4301 (AISI 304) or 1.4404 (AISI 316L)

- Space-saving, compact design

- Drinking water approval (ACS, KTW, WRAS) for all components in contact with the fluid (EPDM version)

Design type

Non self-priming multistage pump

Application

- Water supply and pressure boosting

- Irrigation

- Heating

- In industrial systems (foodstuff industry, renewable energies, shipbuilding): Cooling and washing system

Equipment/function

- Stainless steel in monobloc design

- Threaded connection

- Single-phase or three-phase AC motor

- Single-phase AC motor equipped with built-in thermal motor protection (with automatic restart)

Downloads

Products

| Product description | Mains connection | Gross weight, approx. m | Article number |

|---|---|---|---|

| Economy MHI 202 (1~230 V, EPDM) | 1~230 V, 50 Hz | 11.3 kg | 4024282 |

| Economy MHI 202 (3~400 V, EPDM) | 3~400 V, 50 Hz | 10.4 kg | 4024283 |

| Economy MHI 203 (1~230 V, EPDM) | 1~230 V, 50 Hz | 11.3 kg | 4024284 |

| Economy MHI 203 (3~400 V, EPDM) | 3~400 V, 50 Hz | 10.4 kg | 4024285 |

| Economy MHI 204 (1~230 V, EPDM) | 1~230 V, 50 Hz | 12.1 kg | 4024286 |

| Economy MHI 204 (3~400 V, EPDM) | 3~400 V, 50 Hz | 11.2 kg | 4024287 |

| Economy MHI 205 (1~230 V, EPDM) | 1~230 V, 50 Hz | 13.7 kg | 4024288 |

| Economy MHI 206 (1~230 V, EPDM) | 1~230 V, 50 Hz | 17.2 kg | 4024290 |

| Economy MHI 402 (1~230 V, EPDM) | 1~230 V, 50 Hz | 11.3 kg | 4024292 |

| Economy MHI 402 (3~400 V, EPDM) | 3~400 V, 50 Hz | 10.4 kg | 4024293 |

| Economy MHI 403 (1~230 V, EPDM) | 1~230 V, 50 Hz | 12.2 kg | 4024294 |

| Economy MHI 403 (3~400 V, EPDM) | 3~400 V, 50 Hz | 11.3 kg | 4024295 |

| Economy MHI 404 (1~230 V, EPDM) | 1~230 V, 50 Hz | 13.7 kg | 4024296 |

| Economy MHI 405 (1~230 V, EPDM) | 1~230 V, 50 Hz | 16.7 kg | 4024298 |

| Economy MHI 406 (1~230 V, EPDM) | 1~230 V, 50 Hz | 19.3 kg | 4024300 |

| Economy MHI 802 (1~230 V, EPDM) | 1~230 V, 50 Hz | 17.3 kg | 4024302 |

| Economy MHI 803 (1~230 V, EPDM) | 1~230 V, 50 Hz | 16.0 kg | 4024304 |

| Economy MHI 804 (1~230 V, EPDM) | 1~230 V, 50 Hz | 17.5 kg | 4024306 |

| Economy MHI 1602 (3~400 V, EPDM) | 3~400 V, 50 Hz | 19.7 kg | 4210710 |

| Economy MHI 1603 (3~400 V, EPDM) | 3~400 V, 50 Hz | 22.1 kg | 4210713 |

| Economy MHI 1604 (3~400 V, EPDM) | 3~400 V, 50 Hz | 23.1 kg | 4210715 |

| Economy MHI 205 (3~400 V, EPDM) | 3~400 V, 50 Hz | 15.2 kg | 4210718 |

| Economy MHI 206 (3~400 V, EPDM) | 3~400 V, 50 Hz | 17.4 kg | 4210722 |

| Economy MHI 404 (3~400 V, EPDM) | 3~400 V, 50 Hz | 15.1 kg | 4210725 |

Series Description

Scope of delivery

- Pump with or without carrying frame, depending on the version

- Installation and operating instructions

Type key

| Example: | WJ-203-X-EM |

| WJ | Wilo jet pumps |

| 2 | Nominal flow rate Q in m³/h at optimum efficiency |

| 03 | Index for pump pressure Version 03 with higher pressure than version 02 (no indication of number of impellers!) |

| X | Version without carrying frame |

| [Space] | Portable version with carrying frame |

| EM | Single-phase current, 1~230 V, 50 Hz |

| DM | Three-phase current, 3~230/400 V, 50 Hz |

Technical data

- Mains connection 1~230 V, 50 Hz or 3~400 V, 50 Hz

- Inlet pressure max 2 bar

- Fluid temperature max. +5 °C to +35 °C

- Max. operating pressure 6 bar

- Protection class IP44

- Suction- and pressure-side connection G 1

Materials

- Pump housing made of 1.4301 stainless steel

- Impeller made of 1.4301 stainless steel

- Shaft 1.4005 stainless steel

- Mechanical seal made of ceramic/carbon

- Diffuser/injector made of Noryl

- Seals made of NBR

Special features/product advantages

- User-friendly thanks to its light weight, compact size and practical carrying handle

- High supply guarantee due to hydraulic output, self-priming up to 8 m; even at a low flow rate

- Robust stainless steel construction for durable operation, impeller, shaft and housing made of AISI 304

- IE3-IEC three-phase AC motor (≥ 0.75 kW)

Design type

Self-priming multistage centrifugal pumps

Application

- Pumping water from wells

- Filling, pumping empty, transferring by pumping, irrigation and sprinkling

- As emergency pump for overflows

Equipment/function

- With or without handle, depending on the version

- For single-phase motor ( 1~ 230 V):

- Connection cable with plug

- On/off switch

- Thermal motor protection switch

Downloads

Products

| Product description | Gross weight, approx. m | Article number |

|---|---|---|

| Jet WJ 202 X (1~230 V) | 10.2 kg | 4081221 |

| Jet WJ 203 X (1~230 V) | 11.3 kg | 4081222 |

| Jet WJ 203 X (3~230/400 V) | 10.6 kg | 4212734 |

| Jet WJ 204 X (1~230 V) | 12.3 kg | 4143999 |

| Jet WJ 204 X (3~230/400 V) | 14.4 kg | 4212735 |

| Jet WJ 202 (1~230 V) | 11.0 kg | 4081224 |

| Jet WJ 203 (1~230 V) | 12.0 kg | 4081225 |

| Jet WJ 204 (1~230 V) | 13.0 kg | 4144401 |